Our capacity, experience and

human resources speak for themselves

Feature of ZUE

Variety of parts

The laser machine enables us to offer you a wide range of products, from 1mm sheet to large pieces.

Short custom runs

Our manufacturing process is agile and flexible, adapting easily to the quantities requested.

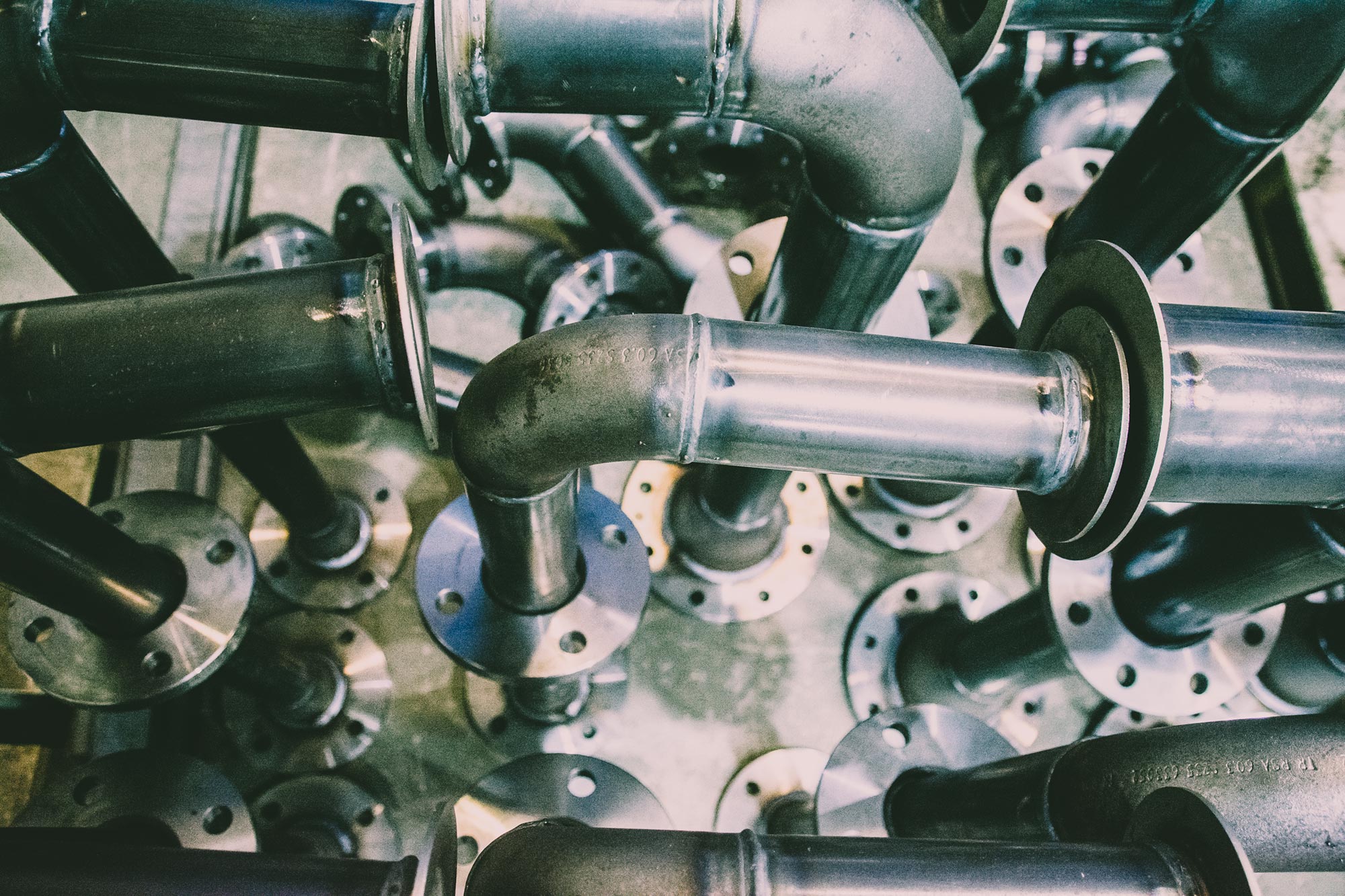

Welding and consultancy

We have approved procedures and welders, as well as certified welding inspectors. Our IWT welding coordinator will advise you on finding the right solution.

Control of deadlines

Our BOLT manufacturing system optimises the manufacturing process. All our staff are aware of the requirements and delivery time for your piece. We guarantee that your expectations will be met.

Total management

We deliver the finished piece to you. We offer a 360º turnkey service. We take care of all the necessary stages in this, including machining, painting and surface treatments.

ZUE solutions

Laser precision for cutting

Trumpf Laser Machine (3000 x 1500), oxygen and plasma cutting machine with CNC control (6000 x 2500), shear, saw, various manual cutting devices.

All kinds of assembly

In our current 2,000 m2 of space we have the means of production necessary to carry out boiler making and assembly work.

Experts in welding

TIG, MIG/MAG for manual and automatic welding processes.

Quality Striving for perfection

We have specific procedures for each production process. These include checks and inspections of all kinds, both internal and external.

Painting Finishing pieces and painting

Application of liquid paint on our premises

Machining

We deliver fully-machined parts according to plans.

Surface treatments

Surface treatments of all kinds: galvanised, dichromated, zinc, blued, etc.

Non-destructive testing

All types of non-destructive tests carried out: penetrating fluid, magnetic particle, coplanarity, etc.

ZUE solutions

Our capacity, experience and

human resources speak for themselves

Laser precision for cutting

Trumpf Laser Machine (3000 x 1500), oxygen and plasma cutting machine with CNC control (6000 x 2500), shear, saw, various manual cutting devices.

All kinds of assembly

In our current 2,000 m2 of space we have the means of production necessary to carry out boiler making and assembly work.

Experts in welding

TIG, MIG/MAG for manual and automatic welding processes.

Quality Striving for perfection

We have specific procedures for each production process. These include checks and inspections of all kinds, both internal and external.

Painting Finishing pieces and painting

Application of liquid paint on our premises.

Machining

We deliver fully-machined parts according to plans.

Surface treatments

Surface treatments of all kinds: galvanised, dichromated, zinc, blued, etc.

Non-destructive testing

All types of non-destructive tests carried out: penetrating fluid, magnetic particle, coplanarity, etc.